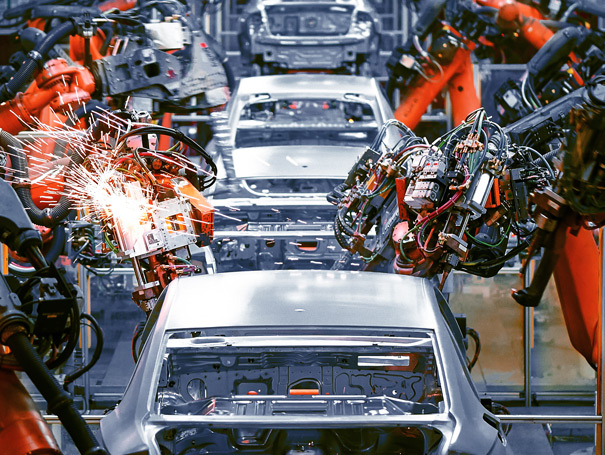

Industrial Automation

Tech Pennar specializes in design engineering and provideIntegrated turnkey industrial automation solutions based on state-of-the-art PLC-SCADA-DCS and other operation technologies. In addition, we provide customized industry specific software interface technologies (IT-OT platform). We offer these specialized solutions across multiple industries that includes- Oil & Gas, F&B, Automotive, Agriculture, FMCG, Infrastructure and Utilities, Mining and Minerals, Metals, Energy, substation automation, HVAC, standalone machines, skids etc. We are the preferred engineering partners for Original Equipment Manufacturers (OEMs), Engineering, Procurement and Construction (EPC) organizations, System Integrators and Solution Providers, process and production companies covering a wide range of industries and applications including the following services:

- Automation solutions

- Electrical & Control panels

- Operation technology-based solutions

- Services

Industry standards followed:IEC- 61131, IEC- 61850, ISA-88, ISA-95, DCP, SIL 2, SIL 3, 21 CFR, Part 11, GAMP and BRAUMAT/ CEMAT.

Among the automation systems and software’s manufacturers our company collaborates with, you can count:

PLC- Siemens – S7- 400 H/ F, 300, S7-1200, S5, S7-1500, Fail-safe Controller, SICAM PAS

- Rockwell Automation – ControlLogix, CompactLogix, SLC-500 PLC 5, GuardLogix

- Schneider Electric – Quantum, Premium, Modicon Mseries, Modicon PAC and Modicon ePAC

- Emerson – RX3i CPE, CPL, RSTi-EP, Rx7i, Series 90-30, Series 90-70, VersaMax

- Honeywell – MasterLogic, Safety Manager & Fail Safe

- Mitsubishi – MELSEC-iQ-R, MELSEC-iQ-F, MELSEC-Q,L,F,QS,WS, A, Series

- ABB – AC500 (eCO, S, XC)

- Omron – NX, NJ, CP, CJ, CS Series

- Siemens – PCS7, SIMATIC Batch

- Emerson – DeltaV, DeltaV Batch

- Honeywell – EPKS C200, C300, R400, R410, HC900, TDC 3000, 2000, TPS/HPM, TDC.

- GE IP – Mark VIe DCS, Proficy batch

- Schneider electric – Ecostruxure (Foxboro, Triconex, Processexpert)

- Rockwell Automation – PlantPAx 5.0, Factory talk view Operation suit

- Wonderware – InBatch

- ABB – 800xA, Freelance

- Siemens: WinCC, WinCC OA, TIA, WinCC Flex

- Rockwell Automation: FactoryTalk View SE/ ME, RSView32, PanelView

- GE Digital: Proficy, iFIX, CIMPLICITY

- Wonderware: InTouch, ArchestrA System Platform, AVEVA Edge

- Inductive Automation: Ignition SCADA

- Schneider Electric: Vijeo Citect, EcoStruxure

- Mitsubishi: MC Works64

- Siemens – SINUMERIK CNC 808, 828, 840

- FANUC CNC – M720 System

- Others – ABB, KUKA, FANUC, Dürr, Bosch etc.

Engineering

Control Panels Design & Engineering

- PLC/IO/HMI/MCC/IMCC & VFD panels design

- Component selection & BOM preparation

- Panels design using AutoCAD Electrical, EPLAN

- Safety and Hazardous location panels

- IP65, HYGENIC panels

- Customized panels

- Procurement, fabrication, and logistics by our permanent registered vendor

System Architecture design

- Automation solutions (Plant network &Terminal network)

- REST (Representational State transfer) for custom designed API

Documentation

- Control philosophy

- Detail Design Specification (DDS)

- Functional Design Specification (FDS)

- System Specific Document (SSD)

- Our Quality Documentation

Software Development (PLC/DCS/HMI/SCADA)

- PLC/DCS programming

- Library development (Industry standard)

- Safety programming

- Batch management & control programming

- HMI development

- SCADA development,

- Historian & Information server configuration and development

- Customized API development for controllers and SCADA

- Bridging and reporting applications

- Part 21 CFR compliance OT applications

- Cross platform applications engineering

- Integrated testing at our PLC/DCS lab

FAT/SAT

- Remote FAT (Simulated environment at our lab)

- Onsite FAT

- SAT

Commissioning & Start Up

- Pre-Commissioning (Installation, Hardware & Network testing, IO testing)

- Start-up

- Controls & Software optimisation

Solutions

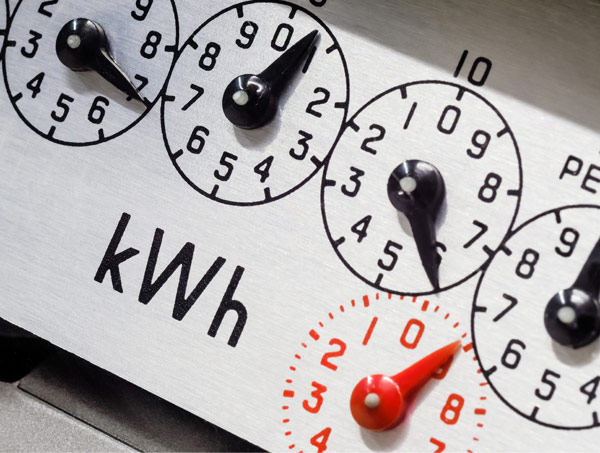

Energy Management SolutionsOptimizing OPEX and CAPEX, utilization result driven solution customized for your facility/factory. EMS collects energy data and uses it for five main purposes:

- Data Collection

- Data Analytics

- Reporting

- Monitoring

- Control

It is system platform independent so, can accommodate and serve on any device with standard industrial communication protocols available in the market.

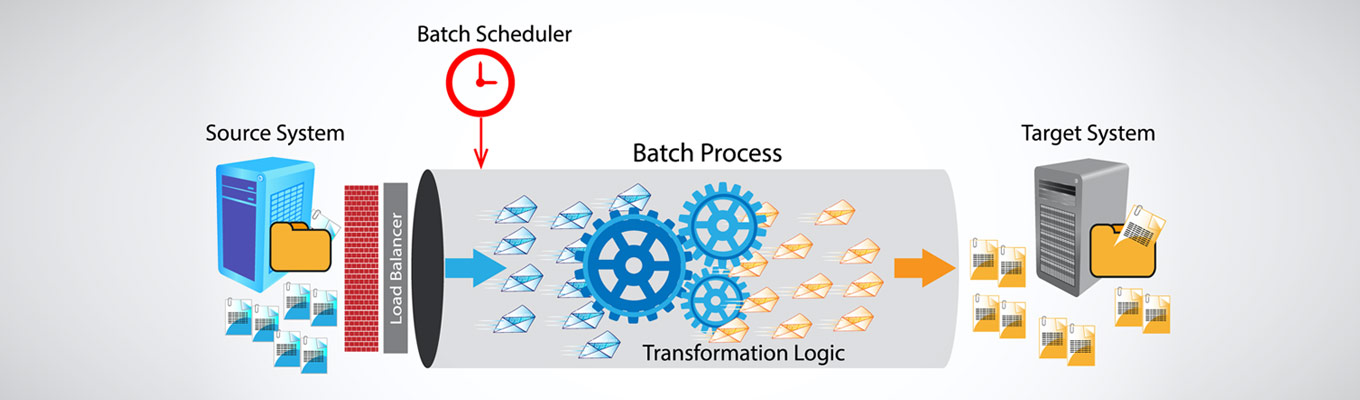

Custom made and economic batch management software, it can serve discrete batch process and continuous batch process. It is integrated with SCADA & PLC with pre-defined library developed using ISA88 and ISA95. standards.

Process & Production Data Analysis

Curiosity application developed on operation technologies to know mass balance data throughout the process. It can be implemented side by side during new process automation project implementation or on a production ongoing project

- Shop floor or Control level

- Automation & Field level

Predictive maintenance evaluates the condition of equipment by performing periodic (offline) or continuous (online) equipment condition monitoring. The ultimate goal of the approach is to perform maintenance at a scheduled point in time when the maintenance activity is most cost-effective and before the equipment loses performance within a threshold.

- Shop floor or Control level

- Automation & Field level

Our suit of services

- Batch manufacturing processes

- Continuous process systems

- Data collection systems

- Historian Systems

- PLC/DCS/HMI/SCADA migrations

- Project service level agreements

- Annual maintenance contract (AMC)

- MES and enterprise data sharing platforms

- Network Design & Support

- OEE and downtime measurement systems

- Process Optimization

- Recipe Management Systems

- Reporting Systems

- System Simulation

- Programmable Logic Controls (PLC)

- Machine Vision Systems

- Robotics

- Component Indexing

- Material Handling

- Project service level agreements

- Annual maintenance contract (AMC)

- In Batch, Simatic batch, Factory Talk Batch, Experion Batch management system programming and integration

- Ingredient inventorying software

- Track and trace for Batch

- Custom economic batch and process control solutions

- Data collection systems

- Historian Systems

- HMI and SCADA integration

- Network design and support

- OEE and downtime measurement

- Project service level agreements

- Annual maintenance contract (AMC)

- Identify opportunities for greater system flexibility and reliability

- Integrate any new technologies

- PLC/SCADA/HMI/DCS software upgradation and Migration

- Control cabinets, PLC & IO panels upgradation

- Justify ROI

- Develop a complete project plan and present to management

- Optimize your automation strategy

- Collect data and map your current system

- Maximize operating up-time during the transition

- Complete and total system checkout and training

- ABB Robot studio programming& onsite services

- Fanuc robot programming & onsite services

- ABB & Fanuc robots interfacing

- Multi-axis motion controllers (Siemens, Bosch & ABB)

- Servo drives: Single and three phase

- Programmable Servo drives

- Servo motors

- Software tools

Project Consultancy Services

- Site survey

- Control Panel & Systems Building

- Power Up & Testing

- Onsite Commissioning